CSBR

CSBR (CSBR, Continuous flow Sequencing Batch Reactor)

CSBR Process

CSBR process, which is economical in terms of footprint and maintenance costs, is suitable for use with medium and large-scale wastewater treatment facilities. It is a city-friendly construction technology that is advantageous for underground facilities.

-

Applied to 20 facilities in Korea;

40 facilities around the world

Features

Features

CSBR is a continuous batch advanced

sewage treatment technology that combines A2O and SBR processes.

-

Composed of anoxic tank, anaerobic tank, and aerobic tank, highly efficient nitrogen and phosphorus removal effect.

-

Continuous inflow/discharge of treated effluent without change in water level within the reaction tank, eliminating separate flow control tank and final settling tank > Minimum site area.

-

The process of repeatedly treating A2O process water with SBR process is excellent for responding to load fluctuations.

-

Quintessence sedimentation/discharge of the SBR tank optimizes SS removal efficiency through optimal sludge solid-liquid separation.

Process Flow

Process Flow

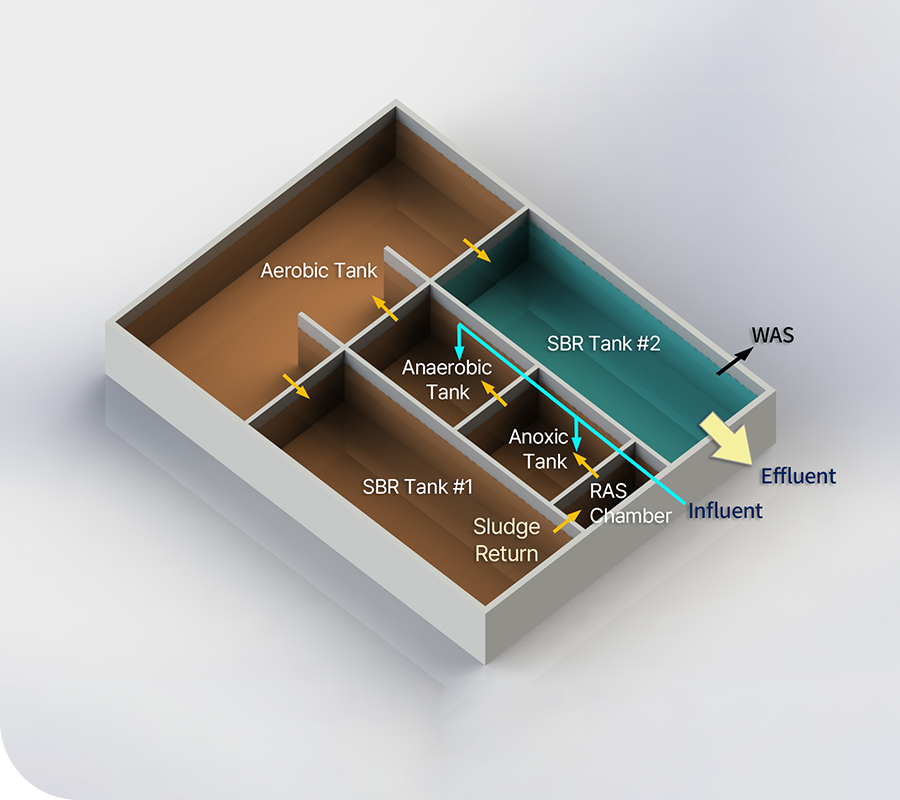

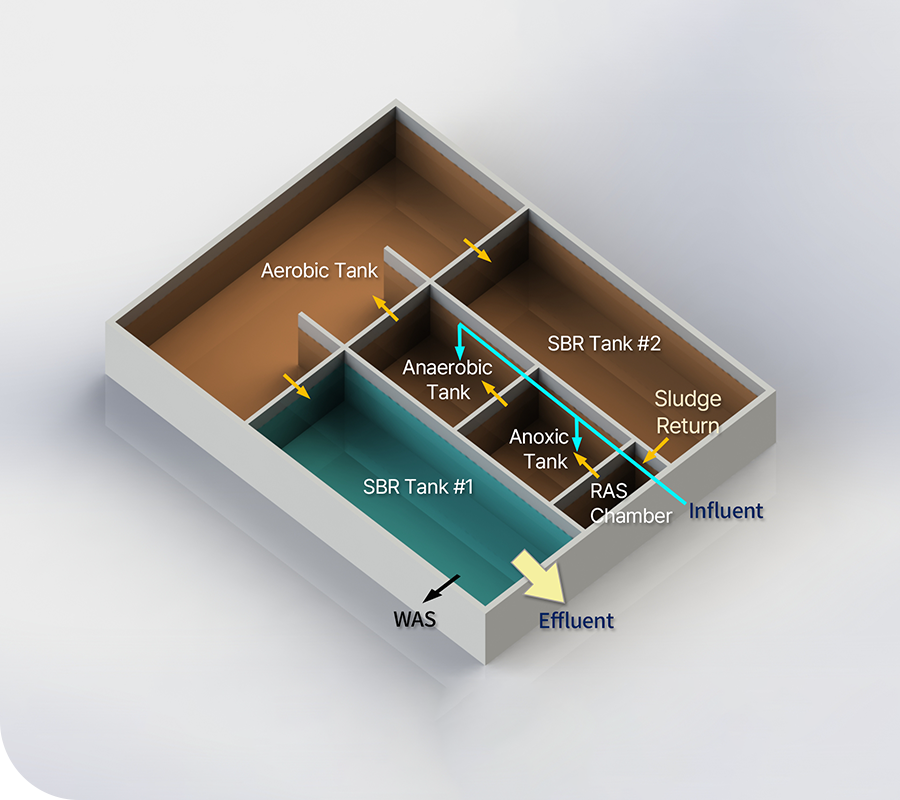

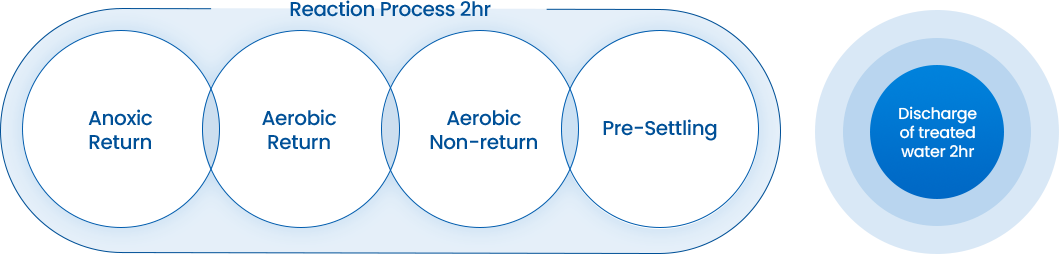

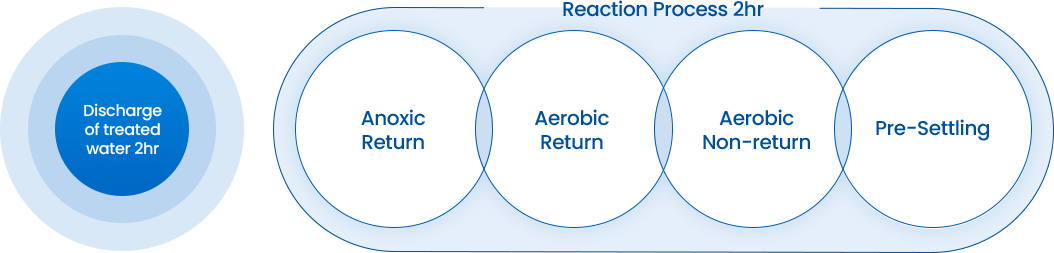

CSBR bioreactor is arranged in a configuration of

continuous flow anoxic tank, anaerobic tank and aerobic

tank (A2O process), followed by two symmetrically configured constant level SBR tanks for recycling activated sludge

(RAS), batch treatment, quiescent settling and decanting of

treated supernatant.

After the influent undergoes anoxic-anaerobic-aerobic reactions,

it flows into the SBR tanks in the form of sludge mixtures (MLSS).

While one SBR tank is in reaction process performing RAS recycling, batch treatment and quiescent settling, the other

SBR tank is in decanting process discharging the treated supernatant. Waste activated sludge (WAS) is withdrawn from the

SBR tank

that is in decanting mode.

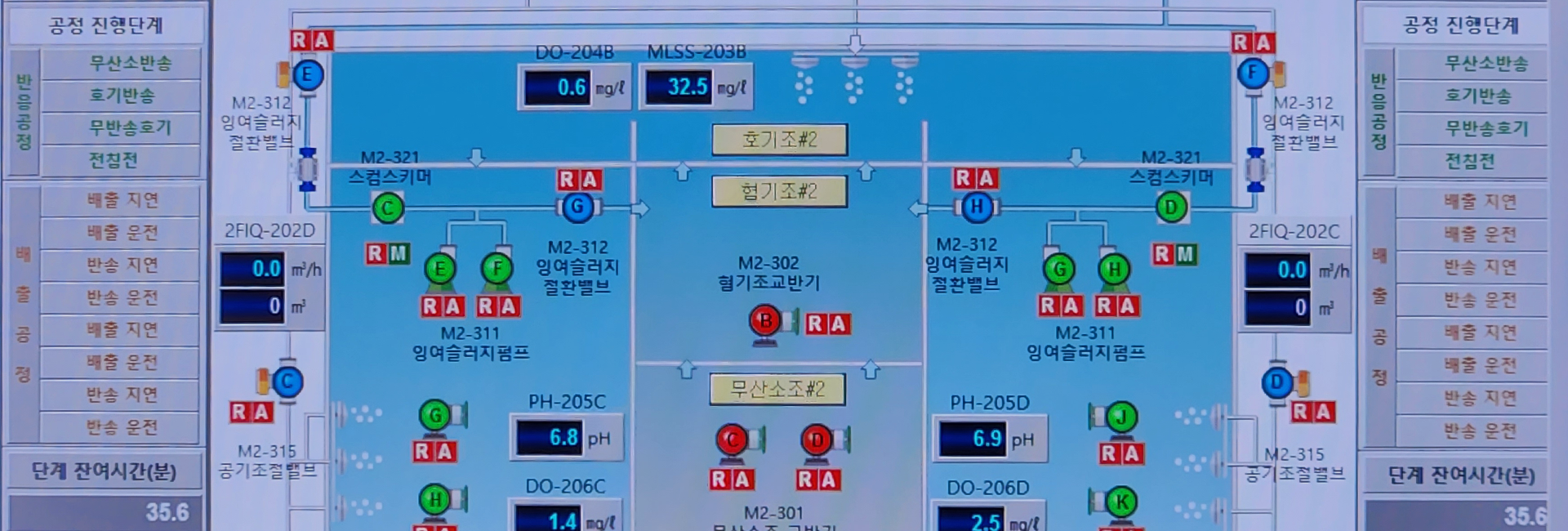

The SBR tanks operate alternately during 24 hours in a cycle basis, and all of these preocesses are automatically

controlled

according to the CSBR operation cycle.

<SBR Tanks Treatment Process>

SBR#1

SBR#2

* SBR tank #1, #2 altanative operation

Excellence of CSBR : Domestic project examples

Excellence of CSBR :

Domestic project examples

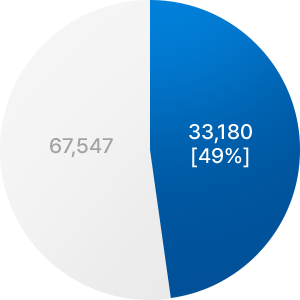

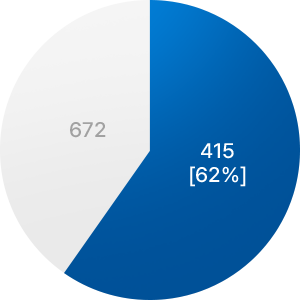

- Capacity: 80,000㎥/d

- year: 2001

<Jinkun STP >

![]() Budget

Budget

![]() CSBR

CSBR

-

Footprint

[Unit : ㎡] -

Construction Cost

[Unit : MM won] -

Operation Cost

[Unit : 100MM won/year]

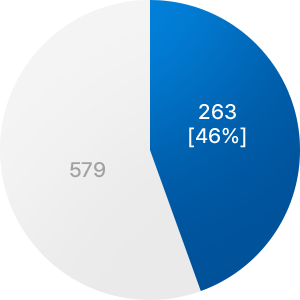

- Capacity: 100,000㎥/d

- year: 2002

<Jinkun STP >

![]() Budget

Budget

![]() CSBR

CSBR

-

Footprint

[Unit : ㎡] -

Construction Cost

[Unit : MM won] -

Operation Cost

[Unit : 100MM won/year]

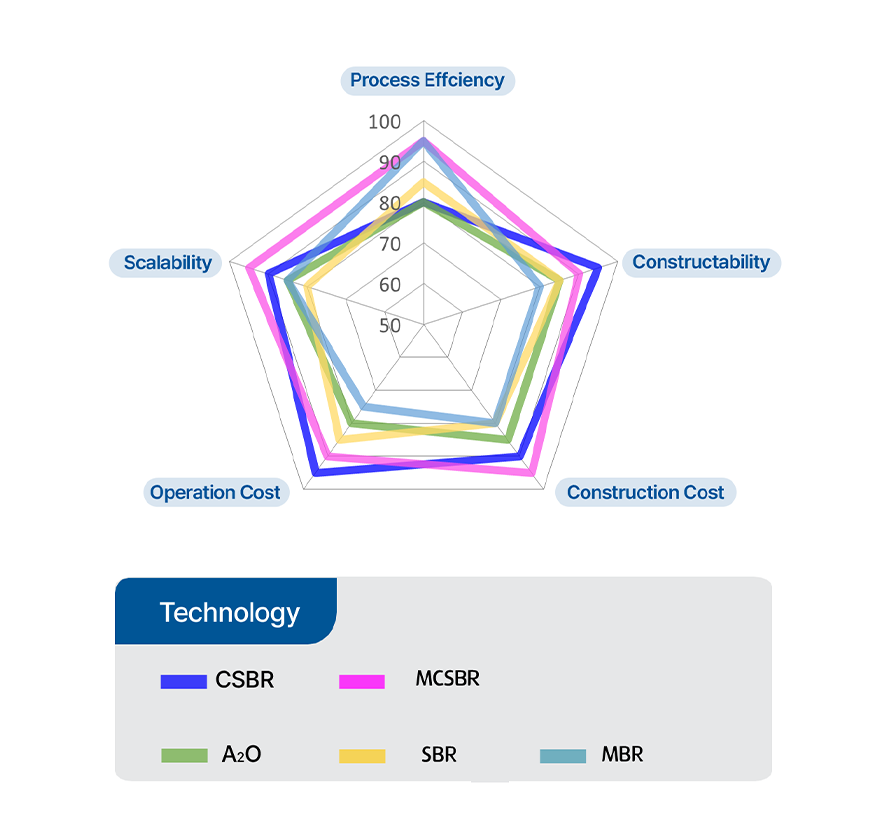

Excellence of CSBR when compared to other technologies

Excellence of CSBR

when compared to other technologies

| Technology |

Process Efficiency |

Construc tability |

Construc-tion cost |

Operating expenses |

Scalability | Total |

|---|---|---|---|---|---|---|

| CSBR | 80 | 95 | 90 | 95 | 90 | 460 |

| MCSBR | 90 | 90 | 95 | 90 | 95 | 465 |

| A2O | 80 | 85 | 85 | 80 | 85 | 415 |

| SBR | 85 | 85 | 80 | 85 | 80 | 415 |

| MBR | 95 | 80 | 80 | 75 | 85 | 415 |

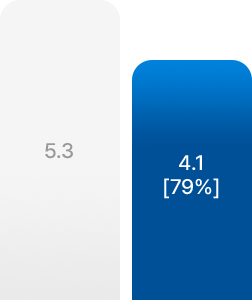

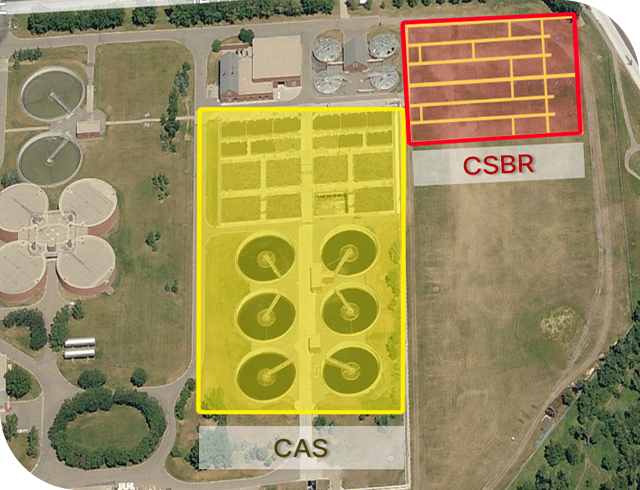

Canada Bonny Brook

50% footprint reduction(2017)

Treatment plant capacity : 123,000 ㎥/day

- When a new CSBR treatment plant with the same

capacity

was constructed, the required area was only 45m,

requiring less than 50% of the site area compared

to the previous Conventional Activated Sludge (CAS)

treatment plant.

Indian Media Reports

Indian

Media Reports

CSBR's superior economic and technical feasibility

was verified by the Brihanmumbai Municipal Corporation

(BMC) through a visit and examination of a CSBR

treatment plant in the Republic of Korea

-

New record in the history of Indian sewage treatment plants with a construction contract at 54% of the original bidding price

Competitiveness seen in the bid for Bhandup 215,000㎥/day sewage treatment plant

Competitiveness seen in

the bid for Bhandup

215,000㎥/day sewage

treatment plant

<Bhandup STP>

- Capacity: 80,000㎥/d

- year: 2001

![]() Budget

Budget

![]() CSBR

CSBR

-

Footprint

[Unit : ㎡] -

Construction Cost

[Unit : MM won] -

Operation Cost

[Unit : 100MM won/year]

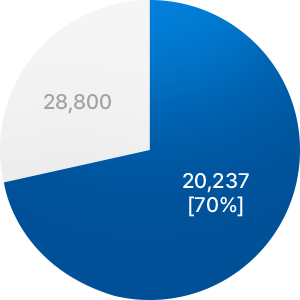

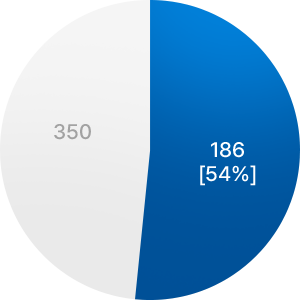

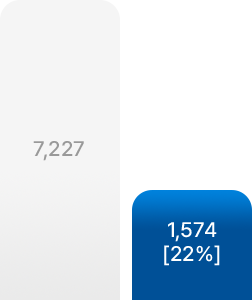

| Process | Footprint (m²) | Construction cost (MMwon) | Power (KW) |

|---|---|---|---|

| SBR | 28,800 | 350 | 7,227 |

| CSBR | 20,237 | 186 | 1,574 |

| Comparative advantage | 70% | 54% | 22% |

CSBR is superior in all aspects including footprint, construction cost, and power consumption.

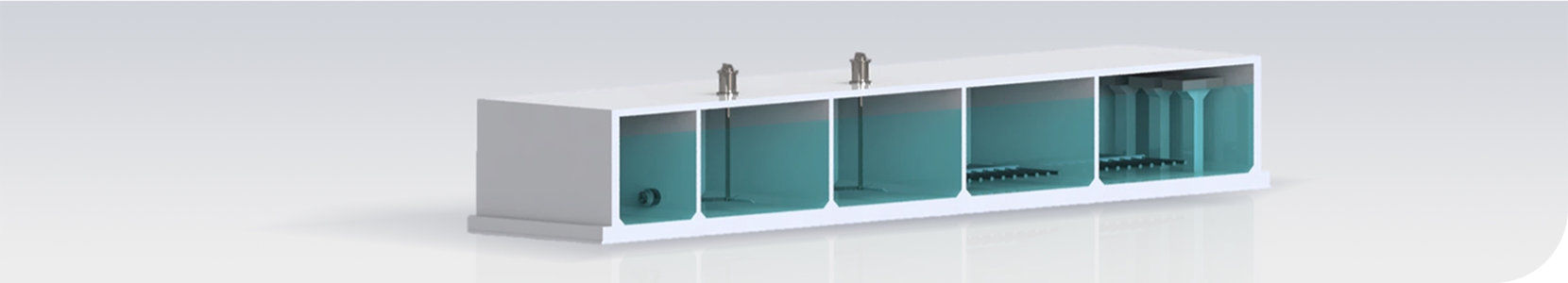

Rothwell Water Main Equipment

Rothwell Water Main Equipment

Treated Water Decanter System

Control Panel System

Diffuser System

| Item | Specifications |

|---|---|

| Material | EDPM(Option: PU/Silicone) |

| Thickness | 1.9mm±0.2mm |

| Density | 1.11±0.03g/m³ |

| Tensile Strength | >7 MPa |

| Enlongation Rate | > 400% |

| Tear Strength | > 7.5N/m |

| Hardness | 40±5Shore A |

Sludge Transfer System

T-RAS System

Scum Removal Device